Injection Molding Automotive Parts: High-Quality Plastic Solutions for Automotive

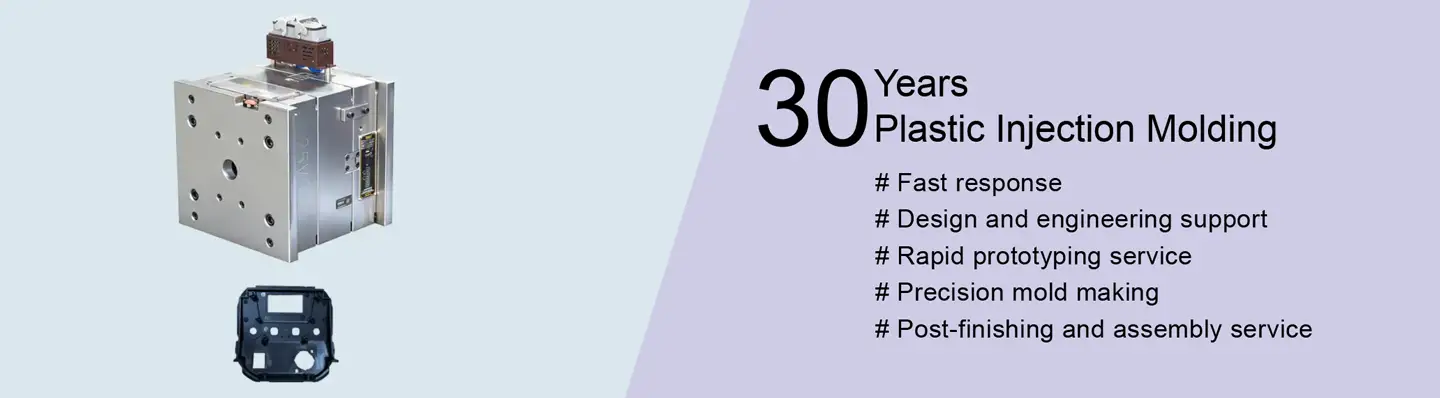

Injection molding plays a defining role in the modern automotive industry, shaping high-quality plastic parts, structural components, and precision assemblies used across nearly every category of vehicle manufacturing. Today, injection molding automotive parts are found in interior components, exterior parts, engine parts, EV systems, lighting elements, and safety-critical assemblies. As automotive