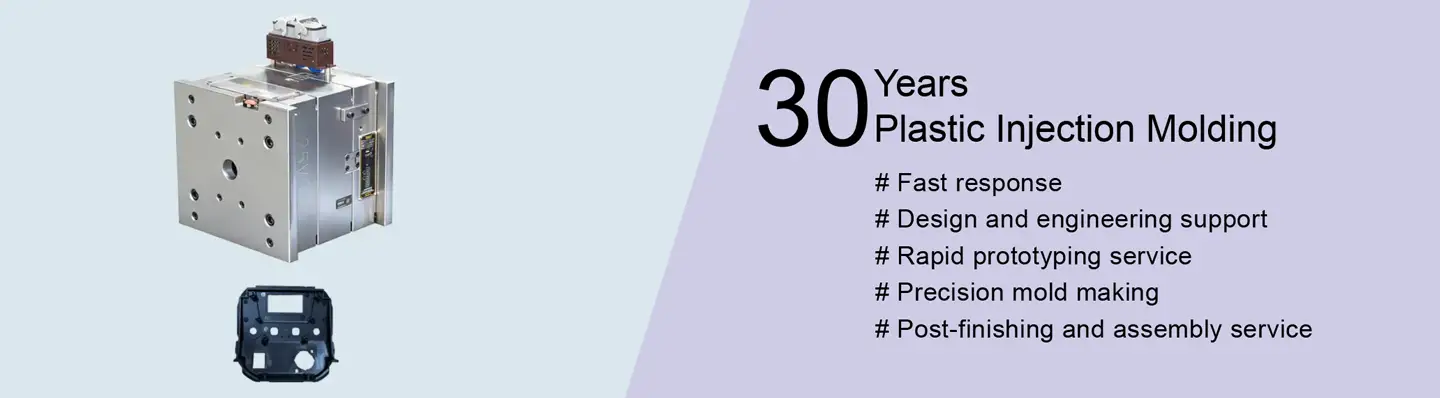

Our Injection Molding Service

Our injection molding service delivers precise, consistent, and cost-effective plastic parts for projects of any scale. From prototype runs to full production, we ensure high-quality molds, fast turnaround, and reliable performance to support your product needs, with design and engineering support, shipment support, post-finishing and assembly service.

Injection mold design

Injection mold design is the foundation of producing precise, durable, and cost-effective plastic parts. By tailoring each mold to the product’s geometry, performance needs, and material selection, we ensure optimal flow, strength, and cycle efficiency. From DFM analysis and steel selection to cooling layout and tooling accuracy, every stage is engineered for reliability. With advanced software, skilled designers, and strict quality control, we create molds that support consistent production across automotive, electronics, construction, and consumer goods industries—turning complex ideas into high-performance molded components.

Learn more

Injection mold making is the core process that transforms product designs into high-precision tooling ready for efficient production. Through careful steel selection, advanced machining, EDM, polishing, and strict dimensional control, each mold is built for durability, accuracy, and long service life. Our skilled technicians use modern equipment and detailed quality checks to ensure smooth mold performance, stable cycles, and reliable part consistency. We deliver molds that turn complex concepts into dependable plastic components.

Learn more

Custom plastic injection molding enables us to deliver fully tailored solutions built around each customer’s specific needs. From early product engineering to mold fabrication and final manufacturing, we maintain precision, durability, and cost efficiency throughout the entire process.

With advanced equipment and a skilled technical team, we produce high-quality components for automotive, electronics, construction, and consumer goods industries. Our flexible production capacity and rigorous quality control ensure every idea is turned into dependable, production-ready plastic parts.

Learn more

Overmolding

Overmolding is an advanced injection molding process that fuses two different materials into one seamless part. It’s widely used to add ergonomic grips, boost comfort, strengthen durability, and enhance overall functionality.

With reliable bonding and tight dimensional control, overmolding is well-suited for automotive, medical, electronics, and consumer products—delivering improved performance along with a refined, attractive finish.

Learn more

Insert molding embeds metal or other pre-made components directly into plastic as it’s being molded, producing strong, dependable, and highly functional parts. This process minimizes assembly work, enhances durability, and maintains precise positioning.

By merging strength, efficiency, and design versatility into one molded piece, insert molding delivers a smart and cost-effective manufacturing solution.

Learn more

Prototype injection molding is a fast, cost-efficient method for producing early-stage molded parts used for design validation, functional testing, and small pilot runs. Using simplified tooling or rapid mold fabrication, it allows engineers to assess fit, performance, and manufacturability before committing to full-scale production.

This approach shortens development cycles, reduces risk, and provides high-quality samples that closely match final production parts—helping teams refine designs and move to mass manufacturing with confidence.

Learn more

Low volume injection molding

Low volume injection molding is designed for producing small to medium quantities of high-quality plastic parts without the cost and lead time of full production tooling. It’s ideal for prototypes, pilot runs, customized products, and market testing where flexibility and speed matter.

With streamlined molds, faster setup, and precise molding control, this process delivers reliable parts while reducing upfront investment. Low-volume molding helps companies validate designs, launch products quickly, and scale production as demand grows.

Learn more

Start your plastic part projects with us

Get a fast, accurate quote for your plastic parts by uploading your CAD files or drawings. Our engineers review your design, recommend suitable materials, and provide a clear cost breakdown if needed. Start your project with confidence and move quickly into production.

LTC Plastic, Your reliable Plastic Injection Moulding Services China

Plastic injection moulding services china, have grown into one of the world’s most competitive hubs for the plastic injection industry, offering a unique combination of cost efficiency, manufacturing speed, advanced engineering, and large-scale production capability.

Global companies—from automotive and consumer electronics to medical devices and industrial equipment—depend on Chinese injection moulding manufacturers for reliable, high-quality plastic parts at competitive prices.

This comprehensive guide provides an in-depth look at how plastic injection moulding services China work, why so many businesses rely on Chinese suppliers, and what to consider when selecting a mold manufacturer or injection molding company for your next project.

Understanding Plastic Injection Moulding Services China

Plastic injection moulding services china is one of the most widely used processes in modern manufacturing. It allows companies to produce identical, high-precision plastic parts, components, and assemblies in low, medium, or high volumes with consistent quality.

In China, the injection moulding industry has expanded rapidly over the past two decades. Thousands of professional mold factories, plastic mould makers, and injection molding companies in China now offer end-to-end services, including:

Injection mold design

Mold making and manufacturing

Plastic injection molding services

Insert molding and overmolding

Rapid injection moulding

High-precision moulding services China

OEM plastic injection parts China

Thermoplastic moulding services China

Custom plastic injection moulding services China

Many suppliers also provide complete tooling and injection molding, engineering support, material selection guidance, and production of plastic components for global brands.

Why China Leads the Global Injection Moulding Industry

China is now considered the world’s largest and most resource-rich market for plastic injection moulding for several key reasons.

Cost-Effective Production

China’s large supply chain ecosystem—including steel suppliers, resin distributors, and machining facilities—helps reduce overall costs for mold manufacturing and plastic production.

This is why many businesses look for low-cost injection moulding China options without compromising quality.

Advanced Technology and High Precision

Modern Plastic injection moulding services China operates advanced CNC machines, EDM equipment, automated molding systems, and precision testing equipment.

High-precision injection molds, multi-cavity tools, and automation-driven moulding processes are now standard.

Extensive Experience in Injection Molding

Most leading suppliers have 10–20 years of experience in injection molding, giving them the expertise to handle complex geometries, tight tolerances, and challenging engineering-grade plastics.

Strong Engineering and Mold Design Capabilities

Professional mold makers in China use advanced software such as:

MoldFlow

UG

Pro/Engineer

SolidWorks

This enables flawless mold design and manufacturing, improved cooling efficiency, and a stable injection molding process.

Fast Lead Times

Thanks to efficient supply chains and large production capacity, China excels in:

Rapid injection moulding

High-volume plastic production China

Fast mold sampling

Quick engineering changes

On-time mass production

Complete Contract Manufacturing

Many factories provide full China contract manufacturing plastics, including packaging, assembly, and logistics for parts made in China that are shipped globally.

End-to-End Plastic Injection Moulding Services China

Reputable Chinese injection moulding manufacturers offer a complete range of services that support your project from concept to production.

1. Mold Design and Engineering

Everything begins with professional mold design.

Chinese mold design teams focus on:

Part structure optimization

Gate, runner, and cooling layout

Material selection

Mold flow analysis

Tool steel selection

Tolerance analysis

Parting line and ejector design

This ensures a high-quality plastic injection mold capable of millions of cycles.

2. Mold Making and Mold Manufacturing

China is the world leader in cost-effective mold manufacturing.

Top facilities offer:

CNC machining

EDM / wire cutting

Grinding and polishing

Fitting and assembly

Mold testing and validation

Whether you need a custom injection mold, precision injection molds, or multi-cavity production tooling, China provides some of the best value in the global moulding industry.

3. Plastic Injection Molding Services

After mold production, suppliers move directly into plastic injection molding services china, including:

High-volume injection molding

Low-volume molding

Thermoplastic molding

Insert molding

Overmolding

Straight injection molding solutions

Custom plastic injection molding

High-quality injection molding

Plastic molded prototypes and production

These services ensure customers receive complete, ready-to-use plastic components for OEM or consumer applications.

4. Surface Finishing and Assembly

China offers nearly every finishing solution:

Painting & coating

Laser etching

Pad printing

UV coating

Ultrasonic welding

Sub-assembly & full assembly

This helps businesses launch fully finished products faster.

5. Quality Control and Testing

High-quality plastic injection moulding services China require strict QC. Reputable suppliers follow:

Incoming material inspection

In-process monitoring

First article inspection

Dimensional measurement

Mold sampling reports

Final quality verification

This ensures reliable plastic injection output across every batch.

Types of Plastic Injection Moulding Services China

As the industry evolved, China developed a wide portfolio of specialised moulding capabilities.

Custom Plastic Injection Molding

China excels at delivering custom plastic parts for different sectors, such as:

Automotive

Consumer goods

Home appliances

Industrial machinery

Electronics

Packaging

Projects often include custom plastic injection, custom tooling, and design optimization.

Insert Molding

China’s factories offer precision insert molding, combining metal and plastic elements, widely used in:

Electrical components

Automotive connectors

Threaded inserts

Mechanical structures

Overmolding

Overmolding adds a second layer of material around a substrate to improve grip, sealing, or appearance.

Rapid Injection Moulding

For prototypes and early production, rapid plastic injection moulding services China supports:

Fast mold sampling

Small-batch manufacturing

Design verification

Time-sensitive product launches

High-Volume Production

China remains the top destination for high-volume plastic production with automated molding systems and high-speed presses.

Thermoplastic Moulding Services China

Factories commonly mould:

ABS

PP

PE

PC

Nylon

TPU

PMMA

POM

These materials suit everything from durable automotive components to everyday consumer gadgets.

How Plastic Injection Moulding Services China Proceed

Producing an injection mold in China follows a structured engineering workflow.

1. DFM Analysis

Manufacturers begin with Design for Manufacturability (DFM) to eliminate risks before tooling begins.

2. MoldFlow Analysis

This identifies potential plastic injection molding defects and solutions, such as:

Warpage

Sink marks

Short shots

Weld lines

Air traps

3. Tool Steel Selection

Common steels include P20, H13, 718H, and S136, chosen based on:

Mold life

Corrosion resistance

Part surface finish

4. Precision Machining

Molds are machined using:

High-speed CNC

EDM / WEDM

Grinding

CNC polishing

5. Assembly and Fitting

Skilled engineers hand-fit mould components for optimal alignment and performance.

6. Mold Testing

Every tool undergoes T0, T1, and final sampling to validate injection parameters.

Choosing the Right Injection Moulding Company in China

Selecting the right partner is crucial. Leading injection molding companies in China typically provide:

Strong engineering communication

Professional mold design

In-house mold manufacturing

Automated production lines

Robust quality control

Experience with global OEM standards

Competitive injection molding quote options

Reliable suppliers include China plastic injection moulding factories, Chinese injection moulding manufacturers, and established plastic molding companies with years of engineering experience.

When evaluating a mold company, consider:

Technical capability

Quality certifications (ISO 9001 / IATF 16949)

Equipment list (injection molding machines, automation, QC tools)

Engineering strength

Mold manufacturing experience

Project management skills

Past projects and case studies

Industries Served by Chinese Injection Moulding Manufacturers

China supports a broad range of industries, including:

Automotive

Suppliers deliver:

High-precision plastic components

Interior/exterior trim pieces

Connectors and housings

Functional clips and brackets

Consumer Electronics

Chinese factories manufacture:

Housings

Buttons

Structural parts

Insert-molded components

Medical and Healthcare

Sterile, high-accuracy plastic injection-molded parts support medical devices and laboratory equipment.

Industrial and Mechanical Parts

Durable thermoplastic components are used in machinery and equipment.

Packaging

China provides complete injection molding packaging solutions, benefiting food, cosmetic, and retail brands.

Why Many Companies Prefer Plastic Moulds from China

Thousands of companies source plastic molds from China because:

Mold costs are 20–50% lower

Lead times are faster

Engineering talent is highly skilled

Factories offer full-service injection molding

Multi-cavity tooling is affordable

Quality is consistently high

China is especially strong in:

Custom injection molds

Precision injection molds

High-volume production molds

Metal inserts and hybrid mold solutions

The Future of Plastic Injection Moulding Services China

China continues to strengthen its leadership with advancements in:

Injection molding automation solutions

Smart manufacturing systems

Eco-friendly molding processes

High-performance polymers

Low-carbon production

AI-enhanced process monitoring

Green solutions in plastic injection molding

The shift toward Industry 4.0 will only accelerate production speed and consistency.

Conclusion

China’s status as the world’s top destination for plastic injection moulding services china is supported by:

Competitive pricing

Mature supply chains

Strong engineering capabilities

Highly experienced mold makers

Fast lead times

Reliable quality control

Complete moulding and finishing services

Broad industry coverage

Whether you need custom plastic moulding services China, OEM plastic injection parts, thermoplastic molding, or high-precision injection molds, China offers unmatched scalability and value.

For businesses looking for injection molding partners, a reputable manufacturer in China can deliver end-to-end solutions—from mould design and tooling to full production of high-quality plastic components.