Low cost injection molding has become one of the most strategic approaches for companies seeking to balance product performance, speed, and budget.

Whether you’re creating prototype injection molding samples, low-volume production runs, or preparing for high-volume mass production, today’s molding technologies and materials make it possible to reduce mold cost, optimize part cost, and accelerate lead time without compromising quality.

From aluminum molds to rapid tooling, 3D printed molds, and simplified mold design, manufacturers now have more choices than ever. In this comprehensive guide, you’ll learn how to lower injection molding costs, choose the right mold, understand the injection molding process, and access affordable solutions from modern injection molding companies.

What Is Low Cost Injection Molding?

Low cost injection molding refers to reducing all cost drivers of the plastic injection molding workflow, including:

- Injection mold cost

- Material cost

- Cycle time and production efficiency

- Tooling cost

- Prototype development

- Mold manufacturing and mold design

- Production volume

The goal is to produce high-quality plastic parts using optimized processes, alternative mold materials, low-cost thermoplastic resins, and efficient injection molding machines—all while keeping cost per part as low as possible.

This approach is ideal for:

- Startups and inventors building functional prototypes

- OEMs testing product development concepts

- Brands needing low-volume injection molding

- Manufacturers validating part design before scaling to high volume

How Injection Molding Costs Are Calculated

The cost of injection molding is driven by three major factors:

A) Mold Cost

The cost of the mold (tooling) is typically the largest investment. Tooling cost depends on:

- Mold material (steel vs aluminum vs 3D printed mold)

- Number of cavities (single-cavity mold vs multi-cavity mold)

- Part complexity

- Surface finish requirements

- Mold design features

- Cooling channel design

- Expected production runs

A traditional steel injection mold for mass production is expensive but long-lasting. A budget aluminum mold is affordable for low volume or prototype production. 3D printed molds provide ultra-low-cost tooling for rapid prototyping.

B) Material Cost

Material affects both performance and budget:

- Commodity plastics → cheap (PP, PE)

- Engineering plastics → higher cost (ABS, PC, Nylon)

- High-performance plastics → most expensive (PEEK, Ultem, PPS)

Choosing the right plastic material can reduce part cost and improve manufacturability.

C) Production Cost

Production cost includes:

- Cycle time

- Machine size

- Resin usage

- Labor

- Scrap rate

- Post-processing

Shorter production cycles and optimized designs lower expenses significantly.

Low-Cost Mold Options: Choosing the Right Tooling

Tooling contributes up to 70% of injection molding cost, so choosing the right mold type is critical.

Aluminum Mold (Most Popular Low-Cost Option)

- Lower tooling cost

- Faster machining

- Ideal for low-volume production

- Great for rapid injection molding

- Supports excellent surface finish

3D Printed Mold

- Best for rapid prototyping

- Inexpensive

- Good for 10–50 parts

- Perfect for early product development

Silicone Mold (Alternative to Injection Molding)

- Used for urethane casting

- Very cheap tooling

- Suitable for small runs

- Not ideal for thermoplastic materials

CNC-Machined Prototype Mold

- Fast turnaround

- Flexible modifications

- Moderate cost

Steel Mold

- Highest durability

- Best for high-volume production

- Higher upfront cost

Techniques to Achieve Low-Cost Injection Molding

A) Simplified Mold Design

A simpler mold means lower tooling cost.

Remove unnecessary details:

- Minimize undercuts

- Avoid complex slides

- Reduce sharp corners

- Use uniform wall thickness

B) Use Cost-Effective Mold Materials

- Aluminum molds → major cost savings

- 3D printed molds → fastest, cheapest

- Hybrid molds → combination of steel and aluminum

C) Choose Low-Cost Thermoplastic Materials

Great budget materials include:

- PP

- HDPE

- LDPE

- PS

- TPE

D) Reduce Part Size and Volume

A smaller cavity lowers:

- Mold cost

- Material cost

- Cycle time

E) Optimize Production Volume

- Low-volume injection molding is ideal for prototypes

- High-volume production reduces cost per part

Low-Cost Manufacturing Alternatives to Traditional Injection Molding

Depending on the stage of development, injection molding may not always be the most economical choice. Consider these alternatives:

3D Printing

- Zero tooling cost

- Perfect for prototypes

- Ideal before investing in mold production

Urethane Casting

- Uses a silicone mold

- Suitable for 10–100 parts

- Fast and cheap

Blow Molding

- Great for hollow parts

- Lower tooling cost than injection molding

Vacuum Forming

- Low tooling cost

- Good for large thin-walled parts

These alternatives to injection molding offer flexibility depending on part design, production volume, and lead time requirements.

Understanding the Low-Cost Injection Molding Process

The standard injection molding process includes:

- Feeding resin into the hopper

- Melting the molten plastic

- Injecting material into the mold cavity

- Holding pressure

- Cooling

- Ejection of the molded part

- Preparing for the next cycle

A well-optimized manufacturing process reduces cycle time, energy usage, and material waste—directly lowering cost.

Low-Cost Injection Molding for Rapid Prototyping

Using aluminum or 3D printed molds, companies can create:

- Proof-of-concept prototypes

- Functional testing parts

- Design validation samples

- Pre-production prototypes

This enables faster product development and reduces delays.

How to Reduce Injection Mold Cost and Part Costs

Key Ways to Lower Mold Cost

- Use aluminum instead of steel

- Reduce mold size

- Use a single-cavity mold

- Standardize components

- Simplify gating systems

- Use rapid tooling methods

Key Ways to Reduce Part Cost

- Choose low-cost resin

- Reduce wall thickness

- Minimize part volume

- Optimize cooling channels

- Use high-efficiency injection molding machines

- Reduce cosmetic surface finish requirements

When Low Cost Injection Molding Is the Best Choice

Low-cost molding is perfect for:

- Startups

- Small companies

- Product testing

- Engineering validation

- Consumer product prototypes

- Kickstarter projects

- Low volume injection molding needs

- Short-run manufacturing

- Bridge tooling before mass production

Applications of Low-Cost Injection Molding

Affordable injection molding is used across many industries:

- Consumer goods

- Electronics

- Tools and hardware

- Medical prototypes

- Automotive small parts

- Industrial components

- Home products

- Toys

- Packaging

- Pilot production

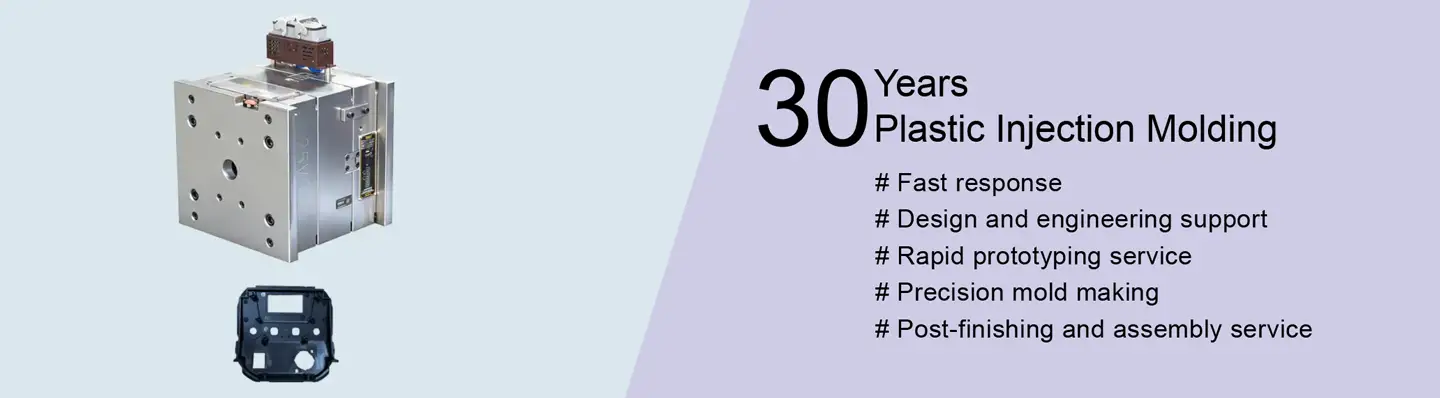

Why Work With a Low-Cost Injection Molding Company?

A professional injection molding company offers:

- Injection molding services

- Material selection guidance

- DFM (Design for Manufacturability)

- Mold design and engineering

- Prototype injection molding

- Rapid tooling

- Part testing

- Custom plastic injection molding

- Post-processing and assembly

Their expertise ensures lower cost, faster delivery, and high-quality results.

The Future of Low Cost Injection Molding Manufacturing

The future of low-cost molding is driven by:

- Automated molding systems

- Desktop injection machines

- AI-assisted mold design

- Low-cost engineering plastics

- Advanced aluminum alloys for tooling

- Industrial-grade 3D printed molds

These innovations will further reduce material cost, mold cost, and lead time, empowering companies to launch products faster and more economically.

Conclusion

Low cost injection molding offers unparalleled advantages for companies seeking affordable, reliable, and fast plastic manufacturing solutions. Whether using aluminum molds, rapid prototyping, 3D printed molds, or simplified mold design, manufacturers can dramatically reduce both tooling costs and cost per part.

With the right molding process, smart material selection, optimized mold manufacturing, and partnership with an experienced mold company, you can achieve:

- Lower production cost

- Faster lead times

- High-quality, repeatable parts

- Scalable production flexibility

Whether you’re creating small parts, testing new product ideas, or preparing for full-scale production, low cost injection molding provides the most efficient and economical path forward.