Company Profile

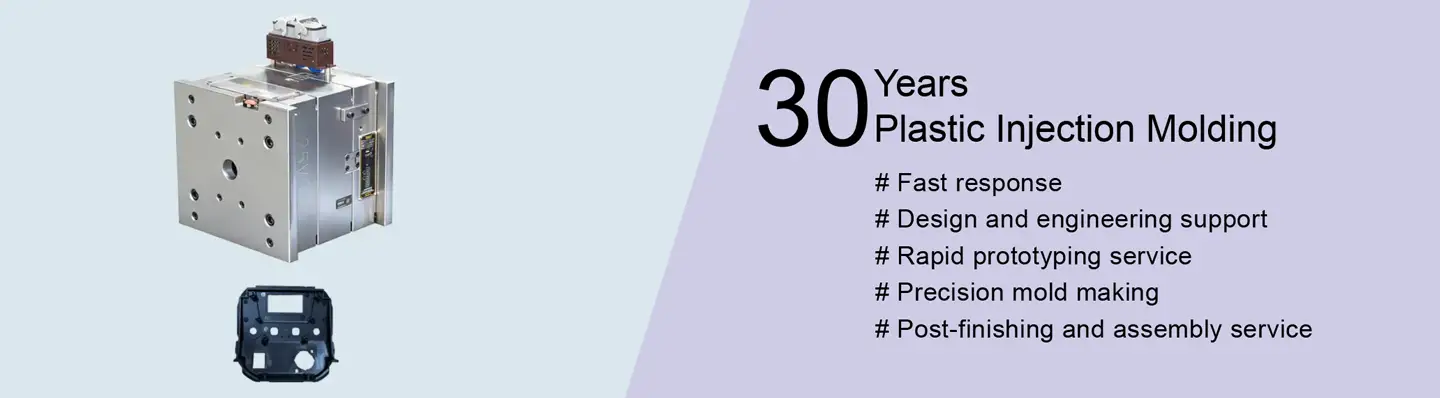

We, LTC Plastic (LZ Tooling Co., Ltd.)are a trusted manufacturer of high-quality injection-molded plastic components, proudly supporting automotive, construction, consumer goods, and many other industries. Equipped with advanced molding machines, skilled technicians, and an experienced engineering team, we consistently produce parts with exceptional precision, durability, and cost efficiency.

Committed to sustainable manufacturing, we offer eco-friendly materials, recyclable plastic options, and responsible production practices that help minimize environmental impact. Our operations follow strict quality management systems and comply with international standards such as ISO 9001, ISO 13485, and IATF 16949, ensuring reliability, safety, and consistent performance in every production run.

When you work with us, you gain a dependable partner delivering innovative, stable, and high-performance plastic solutions—customized to your needs and designed to support long-term growth and success.

Our advantages

LTC Plastic would be your premier plastic manufacturer. We are pleased to customize your plastic parts. We will take care of all your needs, including product design, injection mold design and making, CNC machining, 3D printing, rapid prototyping, post-processing, assembly, quality control, safety compliance, on-time delivery, and shipment arranging. Our team ensures every step runs smoothly with reliable quality and professional support.

#1 Design & Engineering Support

Our design and engineering team turns your ideas into dependable plastic solutions. We assist with material selection, mold design, and product optimisation using advanced engineering tools to ensure accuracy, cost-efficiency, and quicker time to market. Every project receives expert support and customised injection molding solutions tailored to your needs.

#2 Fast and professional response

We prioritise fast response and clear communication. Our team replies to inquiries quickly, offers solid technical support, and provides solutions without delay. From quotations to production updates, we deliver timely feedback, helping you save time and keep every project progressing smoothly, confidently, and efficiently.

We specialise in precision mold design and manufacturing, ensuring every detail meets demanding quality standards. With advanced CAD/CAM software, high-accuracy machining, and thorough mold trials, we build tooling that delivers stable performance, consistent part quality, and long service life. Our technical expertise provides reliable, efficient, and cost-effective solutions for even the most complex injection molding projects.

Our streamlined injection molding process leverages advanced machinery, refined workflows, and skilled technicians to deliver high-quality parts at competitive costs. By reducing cycle times, minimizing waste, and maintaining strict precision control, we consistently produce durable, reliable components. This efficient approach enables us to meet diverse customer requirements across a wide range of industries.

Our Factory

Our factory is equipped with modern injection molding machines, clean production workshops, and efficient assembly lines. With strict quality control, skilled technicians, and a well-organized workflow, we ensure stable output, consistent precision, and reliable manufacturing for projects of all sizes.

# Warehouse

Our modern warehouse is built for safe, organized, and highly efficient storage of both plastic products and raw materials. Using advanced inventory systems, we achieve precise stock control and fast order processing.

Temperature-controlled areas protect product quality, while our streamlined logistics network ensures on-time delivery. This setup allows us to support customers with a dependable supply chain and flexible distribution options.

# CNC machining workshop

Our CNC machining room features advanced multi-axis equipment capable of producing high-precision components and mold parts with tight tolerances. Backed by skilled operators and engineers, we ensure accuracy, consistency, and efficiency across every project.

This setup enables complex mold manufacturing, rapid prototyping, and dependable production of durable, high-performance parts.

# Molds making workshop

Our mold workshop is equipped with advanced tooling machines and experienced technicians, allowing for precise mold fabrication, assembly, and maintenance.

We prioritise accuracy, durability, and efficiency to ensure every mold delivers consistent performance and a long service life. This well-equipped workshop enables fast turnaround and high-quality production of injection molding molds.

# Injection molding workshop

Our production workshop is equipped with advanced injection molding machines, streamlined assembly lines, and rigorous quality control systems. Skilled technicians and engineers collaborate to ensure every product meets international standards for precision and durability.

With efficient workflows and a clean, well-organized environment, we can manage both small-batch and large-scale production with consistent quality and fast turnaround.

Have a custom plastic part project ?

If you have a customized plastic parts project, pls send an inquiry to us, we will follow up and provide a fast and professional solution for your project.